THE M1 MWD SYSTEM

| Sensory Accuracy | Inclination: +/-0.1° I Azimuth: +/- 0.25 |

| Continuous Inc/Az | Inclination: +/-0.2° I Azimuth: +/-0.5° |

| Survey Time | 2 Min (Inc/Az) |

| Signal Transmission | Mud Pulse (Positive) |

| Collar Size | 4.75” OD (3 ½ IF Box/Pin Connection) 6.5” OD (4 ½ XH Box/Pin Connection) 6.75” OD (4 ½ IF Box/Pin Connection) 8” OD (6 5/8 Reg or NC 56 Box/Pin) |

| Flow Range | 4.75″ : 150-350 GPM 6.5″ and 6.75″ : 250-750 GPM 8″ : 300-1000 GPM |

| Sand Content | < 1% by volume |

| LCM Tolerance | 30ppb. Medium Nutplug |

| Battery Life | 450 Circulating Hours |

| Operating Temperature | Series 1: 302°F / Series 2: 349°F |

| Maximum Pressure | 20,000psi |

| Vibration | 50g (g RMS, random, 3-axis) |

| Shock | 1000g (.SmSec, half-sine) |

| Internal Data Logging | Up to 1500 hours |

| Service | Unmanned Service 24/7/365 Support |

MWD

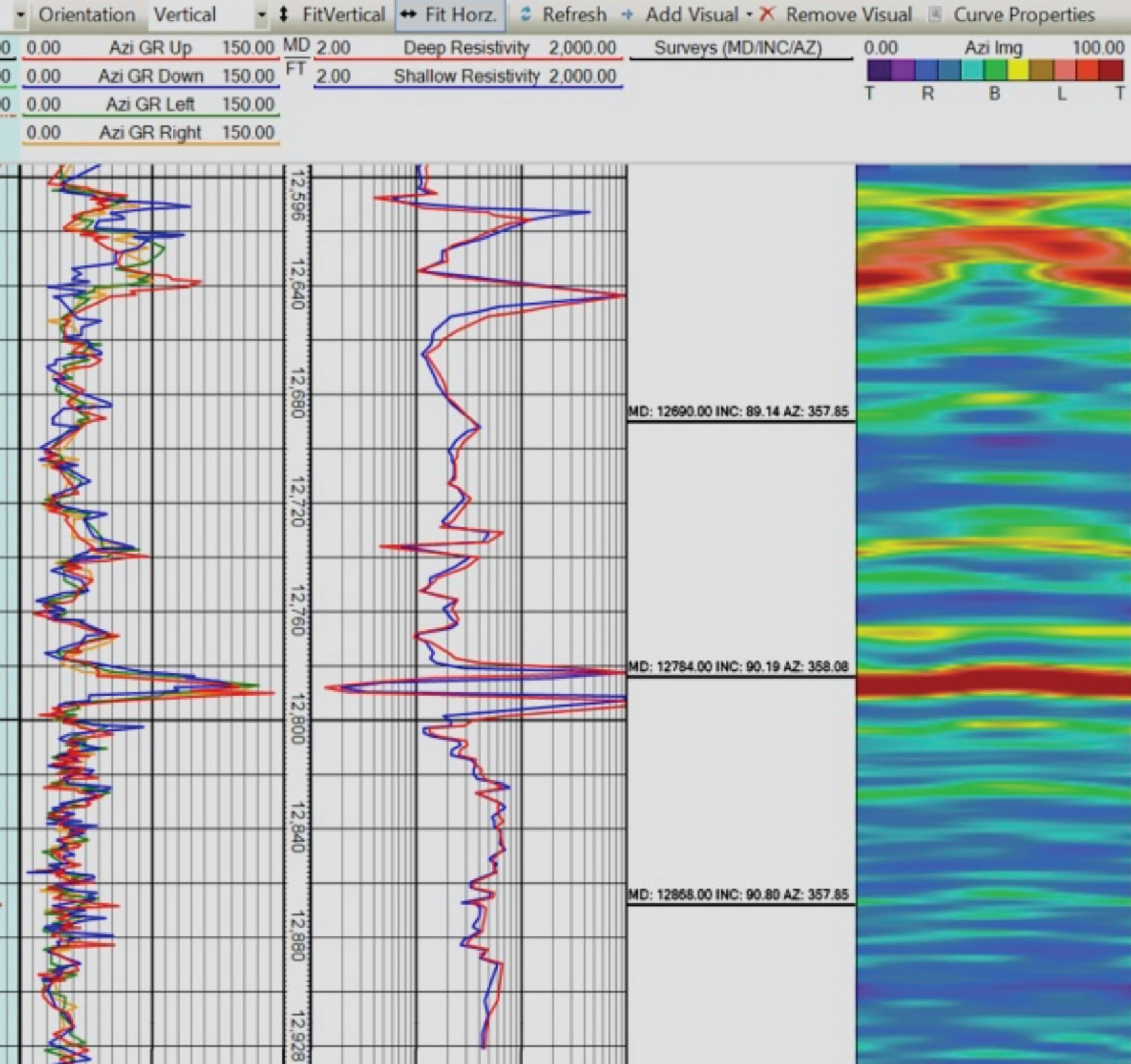

The M1 MWD platform developed by True Shot is the newest proprietary MWD technology on the market. The M1 allows True Shot to deliver the most accurate, fastest, and dependable data in the industry. Throughout True Shot’s 9 years we have drilled over 9,000 runs finding solutions to the ever-changing needs of the drilling industry. The M1 is the latest addition to our fleet created to endure the harshest downhole drilling environments; embodying state-of-the-art materials and technology to withstand high shock, vibration, and lost circulation material. The M1 was designed in the Permian for the Permian to efficiently provide accurate and reliable data across the basin.

UNMANNED MWD SERVICES

The True Shot M1 MWD System is an all-in-one solution for unmanned drilling applications when accurate survey data is required. The M1 deploys the latest in MWD telemetry data providing live and accurate continuous Inclination and continuous Azimuth within 1˚ of accuracy while drilling. This allows for adjustments on the fly reducing dog legs in rotation. The M1 provides high resolution Six Axis Data as well as dynamic sequencing for faster times between connections. The M1 is delivered to your location collar loaded, torqued and high sided ready to run in hole minimizing BHA time. Our dependable technology paired with the most reliable surface decoding software in the industry delivers unparalleled service and quality for all your survey on connection needs. True Shot prides itself on having the ability to pair with any directional provider to ensure the most reliable and cost-efficient packages.

SERVICE HIGHLIGHTS

• On Call 24/7/365

• Wireline Retrievable

• Extended Battery Life

• Minimized Rig Up

• Live Shock and Vibration

• Live Gamma

• Tools Delivered Collar Loaded, Torqued, and High Sided

• Customer Live Access via Computer or Cellular Device to RFD

• Accelerated Data Transmission

• Downloadable Survey Logs

• Proprietary Internal Shock Dampening

• MWD Engineers on Call 24/7

COMMAND CENTER

Our local Command Center actively monitors our MWD operations 24/7 connecting YOU with real time data. Our experienced staff monitors drilling activity providing real time trouble shooting and technical support allowing your operations team to make prompt, precise decisions mitigating unnecessary non-productive time during operations. True Shot Command Center ensures wells are drilled efficiently and accurately. Our Command Center helps eliminate personnel on location reducing HSE and overall costs. Command Center services are in included in all MWD packages, at no additional cost.

THRU TUBING AND

M SERIES EXTENDED REACH TOOL

True Shot’s newest M Series Extended Reach Tool gives operators a leg up on the competition by keeping the string moving laterally and axially, preventing potential stuck pipe situations. Running our M Series ERT combined with our M Series PDM, True Shot gives the operator the ability to make more one run mill outs saving time and money.

M SERIES POSITIVE

DISPLACEMENT MOTOR

True Shot runs the high-performance M Series Positive Displacement Motor for the workover/coil tubing market. We have fluid cooled or sealed bearing pack designs available to meet well specifications along with specific power section fits. The M Series PDM was designed to give operators longer run times to ensure more one run drill outs saving time and money. True Shot has drilled numerous single runs with over 100 plugs drilled in the Permian Basin.

With increasing stages and lateral lengths, the need for a strong combination of torque and movement ensures getting all the plugs drilled.